At Roadmaster, we provide full-service manufacturing solutions across more than 200,000 square feet of cutting-edge production space. Our advanced technology, highly skilled craftspeople, and seasoned engineering team allow us to handle projects of any size or complexity, delivering high-quality, cost-effective solutions for OEM partners. For example, our CNC machine shop offers precision machining services; we are able to produce components from ferrous and non-ferrous metals, alloys, as well as plastics. We provide CNC turning for rotaionals, miling for comples geometries, and swiss machining for small-diamter components.

We offer a variety of manufacturing services to best meet your needs. These include:

Laser Cutting and Plasma Services

Our state-of-the-art fiber and CO₂ laser systems, combined with precision plasma cutting, ensure fast, clean, and efficient material processing.

- Bystronic Fiber Laser: Cuts up to 1/2" mild steel, 1" aluminum, 1/2" brass, 1/2" copper, and 1" stainless steel. Often eliminates the need for bead blasting prior to finishing.

- Bystronic CO₂ Laser: Capable of cutting sheet metal up to 3/8" mild steel and tubes up to 10 feet long.

- Messer Plasma: Two cutting heads handling materials up to 1½".

Induction Forging

Our forging division can handle up to 800 tons, producing precise and durable components.

Forming, Bending, and Sawing

- CNC bending of solids, rounds, squares, and complex shapes up to 2-1/8" solid or 4" tubular.

- CNC press brakes up to 360 US tons.

- Sawing capabilities for aluminum, steel, and stainless steel.

- Coordinate Measuring Machine (CMM) for precise quality verification.

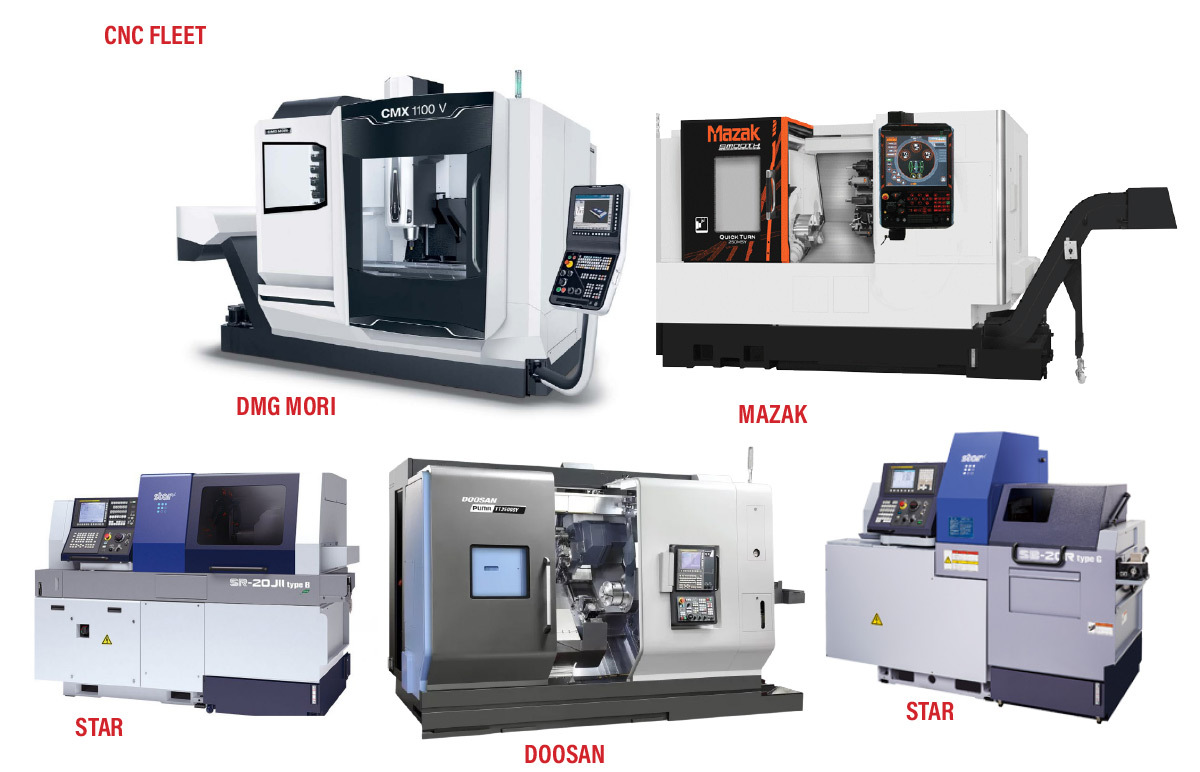

CNC Machining Division

Our advanced CNC machining division works with steel alloys, stainless steel, brass, aluminum, composites, and plastics. Services include profiling, drilling, boring, chamfering, milling, turning, threading, and more.

- Turning: Up to 10'' diameter workpiece and up to 3'' bar feed.

- Miling: Up to 42''x20''x20'' with 40 taper tooling.

- Multi-axis 2-spindle CNC turn-mills with simultaneous vertical and horizontal machining.

- Multi-axis 2-spindle CNC Swiss-turn machine centers.

- 2-axis, 12-tool CNC turning centers.

- 3-axis, 30-tool CNC milling centers.

Surface Finishing and Coating

- Automated Powder Coating: Handles large and small parts simultaneously, with dynamic contour sensing, sandblast preparation, three-stage wash, and fully automated line and batch booth. Available in a wide selection of colors, up to 2’ 3” x 6’ 4”. We use high quality media blasting.

Tooling, Welding, and Fabrication Expertise

- Die building, stamping, and EDM processes in our seasoned machine tool and die division.

- TIG, MIG, and robotic MIG welding for precision assemblies.

- Surface grinding and finishing for superior quality and consistency.

Engineering Services

Our in-house engineering team provides CAD drawing, FEA testing, and expert guidance to ensure projects meet your exact specifications and performance requirements.

Partner with ROADMASTER for Manufacturing Excellence

ROADMASTER’s combination of advanced equipment, expert workforce, and comprehensive manufacturing services allows OEM partners to focus on core business objectives while leveraging our scalable, efficient, and high-quality production capabilities. From concept to finished product, we deliver precision, reliability, and innovation every step of the way.

For any questions you may have regarding our services, manufacturing, or fabrication abilities, please use one of the following methods to contact us, and one of our customer service representatives will be glad to assist you.